When it comes to modern lighting design, innovation and reliability are what truly set great products apart. From architectural highlights to commercial spaces and smart home environments, LED technology has transformed how we experience light. But behind every brilliant lighting installation lies a team of experts — engineers, designers, and technicians — working tirelessly inside a trusted LED Strip Lights factory. And of course, no LED system can shine without the perfect power partner: a LED Power Supply manufacturer ensures every strip, module, and diode performs flawlessly.

China has long been at the forefront of this transformation, emerging as the global hub for LED manufacturing. Today, we’re diving into what makes a top LED Strip Lights factory tick, how technology and craftsmanship come together, and why collaboration with a reliable power supply manufacturer makes all the difference for lighting professionals worldwide.

The Rise of LED Strip Lights in Modern Design

Over the past decade, LED strip lights have evolved from niche decorative accessories to essential lighting tools used in every industry imaginable. From retail stores and offices to homes, hotels, and vehicles, their versatility has made them indispensable.

Unlike traditional lighting, LED strips are flexible, energy-efficient, and easily customizable. They can be cut, bent, and adjusted to fit almost any shape or application. That’s why designers, architects, and contractors prefer them — they bring both creativity and practicality to lighting projects.

At the core of this evolution are factories in China that specialize in LED production. A high-quality LED Strip Lights factory combines precision manufacturing with innovation, ensuring that each LED chip performs consistently while offering superior color accuracy, brightness, and longevity.

Inside a Modern LED Strip Lights Factory

Step into a leading LED Strip Lights factory, and you’ll quickly see that this isn’t your average assembly line. It’s a space buzzing with advanced automation, rigorous testing, and continuous improvement. Here’s what typically goes on behind the scenes:

1. Precision Engineering

Every LED chip starts its journey through automated machines designed to handle micro-level soldering and placement. These machines ensure that each diode sits perfectly on its circuit board for optimal light output and uniformity.

2. Quality Control

Top-tier factories don’t just produce lights — they perfect them. Each strip goes through multiple rounds of testing, including brightness consistency, color rendering index (CRI), and temperature resistance. Quality assurance teams monitor every stage to make sure no faulty strips leave the facility.

3. Smart Customization

What makes the best factories stand out is their ability to create customized LED solutions. Whether it’s RGB, COB, or high-density strips for architectural designs, manufacturers cater to specific client needs. This adaptability is what makes China’s LED industry so globally competitive.

4. Eco-Friendly Production

Sustainability is a growing focus. Many modern LED Strip Lights factories use energy-efficient production methods, reduce waste, and comply with strict RoHS and CE certifications. These standards ensure not only product quality but also environmental responsibility.

Why China Leads the Global LED Industry

China didn’t just become the world leader in LED manufacturing overnight. It’s a combination of technological advancement, scale, and specialization. The country has developed a complete supply chain that integrates everything — from raw materials and components to research and logistics.

Manufacturers collaborate closely with engineers to innovate faster and bring cutting-edge designs to the market at a competitive cost. For clients, this means access to affordable yet high-quality lighting that meets international standards.

The Crucial Partnership Between LED Strip and Power Supply Manufacturers

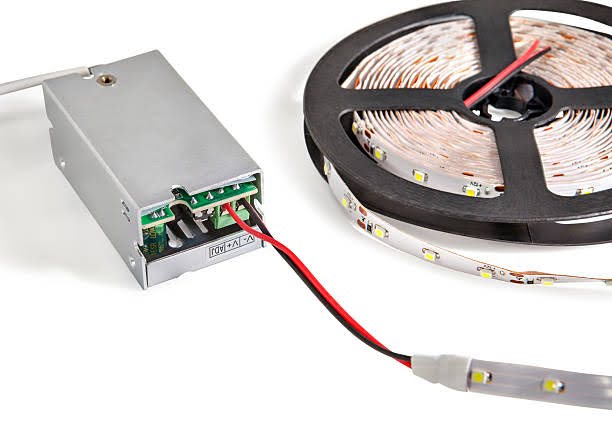

No LED lighting system can function without a reliable power supply. This is where a trusted LED Power Supply manufacturer plays a vital role. These manufacturers design and produce power units that convert high-voltage AC into stable, low-voltage DC power suitable for LEDs.

A great LED strip is only as good as the power source feeding it. The power supply ensures steady current, flicker-free performance, and long lifespan. When factories producing LED strips and power supplies collaborate, the result is a seamless lighting ecosystem where every component complements the other perfectly.

For example, when you use waterproof LED strips outdoors, they must be paired with waterproof power supplies to ensure consistent operation even in harsh weather. Similarly, dimmable LED systems require smart drivers that sync with controllers for smooth brightness transitions.

This kind of precision engineering and compatibility doesn’t happen by chance — it’s the outcome of a strong partnership between LED Strip Lights factories and power supply experts working side by side.

The Innovation Driving Modern LED Manufacturing

The LED industry thrives on innovation. Every year, factories introduce new designs and technologies to improve brightness, efficiency, and color performance. Some key innovations include:

1. COB (Chip on Board) Technology

COB LED strips offer smoother and more uniform illumination, eliminating visible light dots. They’re becoming a favorite among designers for architectural and display applications.

2. Smart LED Strips

Integrated with IoT technology, smart LED strips can connect to Wi-Fi or Bluetooth, allowing users to control brightness, color, and timing directly from their smartphones or smart home systems.

3. Enhanced Heat Dissipation

Modern LED strips use advanced aluminum substrates and silicone coatings to manage heat effectively, ensuring longer operational life and consistent brightness.

4. Energy-Efficient Drivers

Power supply manufacturers are now integrating intelligent control circuits that automatically adjust voltage and current for maximum efficiency and reduced energy consumption.

These continuous innovations keep the industry dynamic, sustainable, and customer-focused.

What Makes a Great LED Strip Lights Factory

Not all factories are created equal. The most reliable ones share some common characteristics that make them stand out in the market:

Strong R&D capabilities: They continuously develop new products and technologies.

Quality assurance: Every production stage is monitored with strict testing procedures.

Certifications: Compliance with global safety standards like CE, RoHS, and UL.

Customization services: Offering tailor-made solutions for clients worldwide.

Efficient logistics: Fast turnaround and global shipping networks.

Choosing a factory with these strengths ensures that you’re getting durable, efficient, and future-proof lighting solutions.

Why Professionals Choose to Work with Chinese Manufacturers

Professionals around the world prefer working with Chinese LED manufacturers for three simple reasons — cost, consistency, and capability.

When sourcing directly from a LED Strip Lights factory in China, clients benefit from competitive pricing without compromising on quality. Factories can produce large volumes while maintaining consistency, which is essential for large-scale commercial projects.

Additionally, many manufacturers provide end-to-end services, from design and customization to packaging and delivery. This makes it easy for businesses to manage projects efficiently and maintain brand standards.

FAQs About LED Strip Lights Factories and Power Supply Manufacturers

1. What makes a good LED Strip Lights factory?

A reliable factory focuses on quality control, innovation, and customization. It should be certified, transparent, and responsive to client needs.

2. Why is the power supply so important for LED strips?

The power supply ensures that LEDs receive the correct voltage and current, preventing flickering, overheating, and premature failure.

3. Can I order customized LED strips from a factory in China?

Yes. Many factories offer customization in color temperature, voltage, size, and waterproofing levels to match your exact project requirements.

4. Are Chinese LED Strip Lights factories eco-friendly?

Top-tier factories are adopting green manufacturing practices, minimizing waste, and complying with RoHS and CE standards to ensure sustainability.

5. What certifications should I look for when choosing a factory?

Look for CE, RoHS, UL, and ISO certifications. These ensure compliance with safety and quality standards.

6. How can I ensure compatibility between LED strips and power supplies?

Always choose both components from trusted suppliers or manufacturers who can verify compatibility based on voltage and current requirements.

Conclusion:

The world of LED technology is evolving at an incredible pace, and the synergy between a leading LED Strip Lights factory and a reliable LED Power Supply manufacturer is what keeps this progress glowing. Together, they’re redefining how we light our homes, businesses, and cities — one innovation at a time.From high-density COB strips that illuminate with precision to energy-efficient power supplies that sustain performance, the combination of expertise and technology in China’s LED manufacturing sector continues to set global standards.For contractors, designers, and distributors seeking durable, energy-efficient, and customizable lighting, choosing the right factory and power supply partner isn’t just a business decision — it’s an investment in quality and trust.Because when innovation meets reliability, every project shines brighter, lasts longer, and performs better — just as great lighting should.